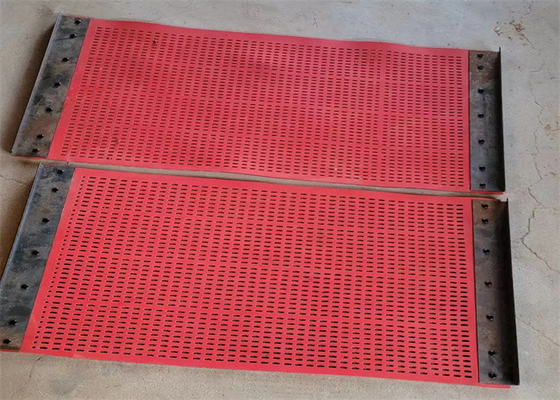

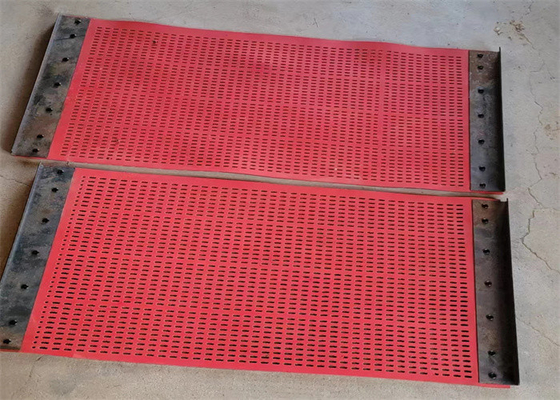

8mm Thickness Round Hole Self-Cleaning Vibrating Rubber Screen Panel

Description of self-cleaning rubber screen panel

Self-cleaning rubber screen panels are specialized screening solutions used in various industries, particularly in mining, aggregates, and recycling. Constructed from durable rubber compounds, these panels feature a unique design with apertures that resist clogging and blockages during material screening. Their flexible nature allows them to vibrate, flex, or bounce, effectively shedding lodged particles without manual intervention. This self-cleaning capability ensures continuous operation, reducing downtime and maintenance needs while enhancing overall screening efficiency in industrial processes.

Specification of self-cleaning rubber screen panel

| Product Name |

Self-cleaning rubber screen panel |

| Material |

Rubber imported from Thailand |

| Screen Width |

1 m or 1.25 m |

| Screen Length |

Can be customized according to your request |

| Thickness |

6 mm, 8 mm can be customized |

| Aperture Size |

Min 3 mm, 4-12 mm generally |

| Aperture Shape |

Generally round shape, rectangle shape can be customized |

| Installation Method |

Hook installation |

Features of self-cleaning rubber screen panel

1. Self-Cleaning Capability: Compared with pu panel, the design incorporates flexible rubber that vibrates, preventing material clogging or blinding, ensuring uninterrupted screening.

2. Durability: These screens are crafted from resilient rubber materials reinforced with steel or other durable components, enhancing their ability to withstand wear, impact, and harsh conditions.

3. Versatility: They efficiently screen diverse materials, including those with varying sizes, shapes, and moisture levels, without compromising performance.

4. Reduced Maintenance: By preventing clogging, they minimize downtime and the need for frequent cleaning, reducing maintenance efforts and costs.

5. Noise Reduction: The rubber construction absorbs vibrations, leading to quieter operation compared to traditional metal screens.

6. Customizable Options: Available in different aperture sizes and configurations, offering versatility to accommodate specific screening requirements.

7. Corrosion Resistance: Some variants are corrosion-resistant, making them suitable for challenging environments.

8. Environmental Friendliness: Certain models use recyclable materials, promoting eco-friendliness and reducing environmental impact.

Application of self-cleaning rubber screen panel

1. Mining and Minerals: Used in mining operations to screen and separate ores, coal, and other minerals. They prevent clogging caused by fine particles and ensure optimal productivity.

2. Aggregate Processing: Found in quarries and aggregate processing plants, these screens efficiently separate gravel, sand, and other aggregates, ensuring high-quality final products for construction and infrastructure.

3. Recycling Facilities: Employed in recycling plants to sort and separate various materials like plastics, glass, metals, and other recyclables, aiding in the recycling process and improving material recovery rates.

4. Construction: Applied in construction sites to separate and grade materials like crushed stone, sand, and gravel for use in building and infrastructure projects, maintaining consistency and quality.

5. Waste Management: Utilized in waste sorting facilities to screen and separate different types of waste materials, facilitating recycling efforts and proper waste disposal.

6. Industrial Processes: Used in diverse industries such as food processing, pulp and paper manufacturing, chemical processing, and more, where precise material separation is crucial for production efficiency.

Gallery of self-cleaning rubber screen panel

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!