Polyeater Blude Matpre-heater Belt for the Wood-based Panel Manufacturing

Huatao's Matpre-heater belt for wood-based panel board has good flexibility, easy deviation correction, firmness and durability. It is widely used in the artificial board industry and is well-known at home and abroad.

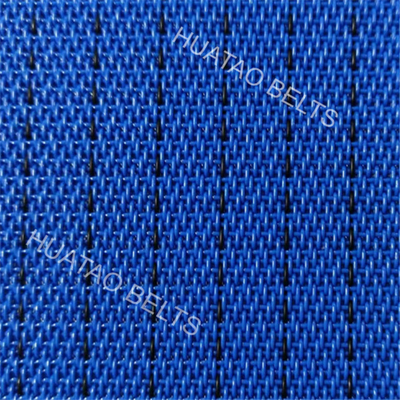

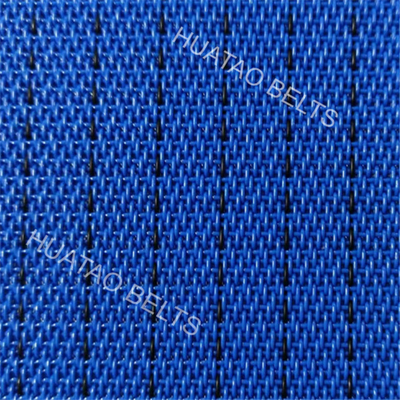

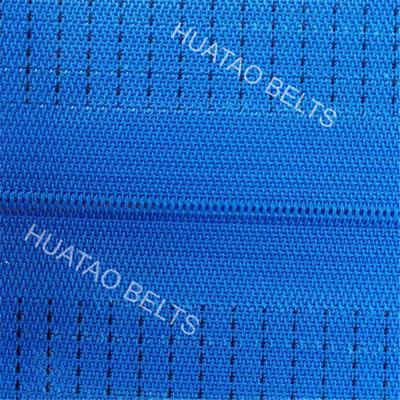

Matpre-heater Belt Photos for reference:

Company Introduction:

Huatao has been focusing on wood-based panel belts for more than 20 years. Through continuous research and development and experiments in recent years, it has been proved that our products are targeted and applicable to all MDF, HDF, PB, OSB (particle boards, medium fibers, oriented strand boards), cardboards and softboards. At present, it has been widely used in machine such as Simbelcomb, Dieffenbacher, Shanghai Board Machine, Dunhua Yalian, etc. at home and abroad, and is well received by customers.

In order to satisfy the needs of equipment and achieve customer satisfaction, we have independent weaving, jointing, heat setting, coating and other advanced equipment and processes, as well as a large after-sales team to provide customers with high-quality services.

Based on many years of experience in the wood industry, through understanding of actual working conditions, continuous optimization of conveyor belt raw material formula and adjustment of production process, Huatao wood conveyor belt has professional mesh belt design models for raw material drying, pre-pressing and ventilation, preheating and steaming, and press entrance. According to different models, different wood-based panel products, and different use parts, the most suitable mesh belt is matched to customers to obtain the best use effect and improve customer production capacity.

There are mainly the following types of polyester mesh belts used in the wood-based panel industry:

1. The Intermediate belt must pass through the bull nose roller (6 mm thin shaft), and it can still maintain balanced conveying, easy to correct deviation, strong and durable, and high temperature resistant. We use a special monofilament woven surface with a special coating treatment and a spiral interface (instead of hot pressing) to meet the equipment's requirements for mesh belts, which is convenient for installation and greatly shortens downtime, ensuring the continuity, stability and efficiency of modern industrial production.

2. The Pre-heater Belt has good heat dissipation, stability, wear resistance and other characteristics, making the slab forming effect more obvious, and adopts spiral ring and pin ring interface

The Matpre-heater Belt has high temperature resistance and good air permeability, effectively preventing the retention of bubbles in the slab, making the fibers more tightly combined; with unique antistatic effect and reasonable weaving pattern, it effectively improves the fiber support index.

The steam-preheater belt for wood industry plays a vital role in the production process of density board and particle board. When the slab is compressed, water vapor with a certain temperature and pressure is sprayed into the slab through the steam injection hole on the pressing plate. The water vapor rushes from the slab to the core layer, heats the fibers and the flowers, rapidly increases the overall temperature of the slab, promotes the rapid solidification of the adhesive, and improves the production efficiency of the board industry. The steam-spraying mesh belt must effectively ensure the discharge of steam inside the fiber, prevent the generation of bubbles in the slab, and quickly transport and dry the adhesive. The advantages are strong anti-sticking properties, good air permeability, and strong thermal stability.

3. The Ventilation Belt adopts special silk thread, which is wear-resistant and tensile-resistant and can adapt to any chemical substances introduced in the artificial board industry, making the mesh belt have excellent breathability. The anti-static black silk thread makes the mesh belt have good anti-static and anti-sticking properties, effectively preventing the fiber from blocking the mesh belt and improving production efficiency. The joints use endless, pin ring, and spiral ring, which can be selected according to the specific use of customers.

4. The Forming Belt has the characteristics of strong structural stability, easy correction and strong wear resistance, which effectively prevents the deviation of the mesh belt and improves the work efficiency. The joints can use steel card joints, spiral ring joints, etc.

5. Polyester drying belt is professionally used in food drying, non-woven fabric production, sludge drying, organic fertilizer production, feed drying, particle board sawdust drying and other industries. It uses high-quality high-viscosity polyester slice wire, which is formed, woven, sorted and shaped. It has unique high-quality properties:

1) It is acid-resistant, alkali-resistant, wear-resistant, and high-temperature resistant (can be operated for a long time in an environment of 180 degrees), and its service life is several times that of other materials.

2) The mesh surface is flat, the tensile strength is high, the air permeability is good, and the heat transfer efficiency is high, which can save energy and cost for users

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!