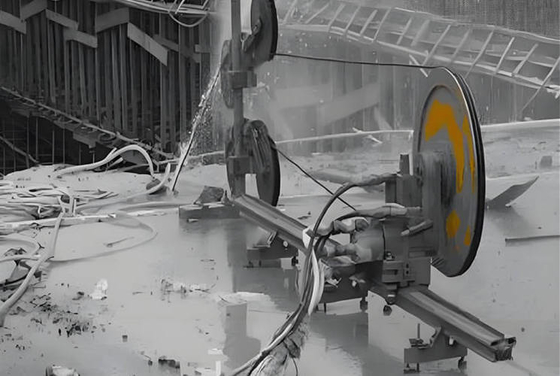

High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry

Description For High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry:

1. Core Material: South African imported diamond beads welded to steel rope, certified by tests, with 40% higher wear resistance.

2. Cutting Capacity: Penetrates 2.2m-thick reinforced concrete walls, supports stepless speed regulation from 0-25m/min.

3. Application Scenarios: Bridge demolition, nuclear power plant containment cutting, ancient building stone processing.

4. Power Configuration: Hydraulic model suits off-grid field sites (e.g., African hydropower projects), electric model with noise <75dB.

5. Tensile Strength: 2,800MPa steel core rope, withstood 3.5 tons vertical tension without deformation during Expressway expansion.

6. Accessory Support: Includes 3 sets of spare diamond beads, compatible with 90% of hydraulic hosts on the market.

Specification For High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry:

| Product Name |

High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry |

| Wire Diameter |

6–12 mm |

| Bead Spacing |

20–40 mm |

| Power Source |

Hydraulic (common for heavy-duty), electric, or diesel-powered |

| Speed |

Adjustable cutting speed |

| Cutting Capacity |

Can slice through thick concrete (up to several meters in depth) |

Key Components For High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry:

1. Diamond Wire: Steel wire with diamond-embedded beads for abrasive cutting.

2. Pulley System: Guides the wire in a continuous loop around the cutting surface.

3. Power Unit: Hydraulic or electric motor providing high torque for smooth operation.

4. Tensioning System: Maintains optimal wire tension for efficient cutting.

Advantages For High-Speed Hydraulic Concrete Cutting Wire Saw For Stone And Masonry:

1. Minimal Structural Damage: Reduces collateral vibrations compared to jackhammers or blade saws.

2. Efficiency: Faster than traditional methods for large-scale cuts.

3. Flexibility: Can perform curved, horizontal, and vertical cuts.

Safety Considerations

1. Dust Control: Water suppression or dust extraction systems.

2. Wire Integrity: Regular inspection to prevent snapping under tension.

3. Operator Training: Required due to high-tension machinery risks.

Think about it: less downtime, more bang for your buck, and gear that stands up to the toughest jobs. That's what our happy clients across 30+ countries are raving about. Don't let this chance slip through your fingers—grab the equipment pros trust and get a quote tailored to your project. Let's make your next job a whole lot easier!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!