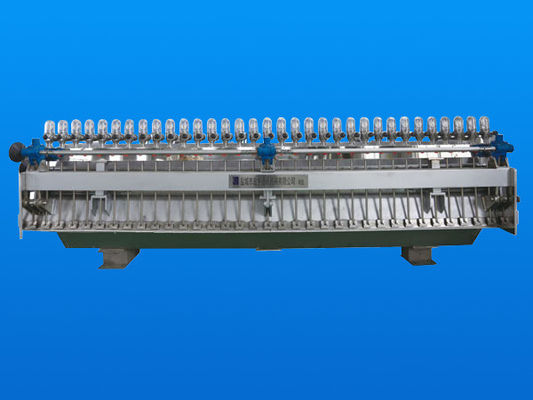

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Description:

Headbox, as an important paper machine part, is the first part from pulp making to paper production. It plays the role of bringing paper pulp to paper machine in pulp flow system. According to the paper type and grade paper machine produces, the quantity of headbox is varified.The headbox is composed of distributed pulp device, well-distributed pulp device, lip device, box body, air supply system and computer control system.

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Distributed pulp device

1.The distributed pulp device adopts the tapered main pipe to enter the pulp, and the three steps diffuse the pulp. The tapered header is composed of inlet flange, large end connection pipe, conical main body, small end connection pipe and outlet flange.

2.The tapered header is equipped with a pressure balance indicator tube, which is convenient to adjust the pressure balance of the tapered header into the pulp.

3.The cone segment can be turned down for cleaning.

4.Taper pipe stainless steel 304.

5.Three - step diffusion material for plexiglass.

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Well-distributed pulp device

1.The well-distributed pulp device is two doctor rollers (lip doctor roller and throat doctor roller), with double spiral holes and quality stainless steel pipe (304).

2.The parameters such as the diameter of the doctor roller and the opening rate are determined according to the process requirements.

3.The doctor roller drive adopts the speed worm gear box and is equipped with frequency converter for speed adjustment.

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Lip device

1.The lip device is composed of upper and lower lip plates, fine-tuning mechanism and lip opening indicator.

2.The upper lip plate is a special joint structure. Can up and down, before and after adjustment lip opening.

3.Manual worm gear box is used to adjust the opening of upper lip plate, and the opening of lip mouth is 5-70mm, which is convenient for operation and maintenance.

4.The outlet of the upper lip plate is provided with a small upright lip plate, which makes the extruded slurry diffused through sudden contraction to obtain a better uniform distribution of slurry. The vertical small lip plate is adjusted by the precision worm fine adjustment mechanism, equipped with a dial indicator device, accurate and flexible, and can directly display the adjustment quantity of small lip plate. Small vertical lip plate removable and replaced with stainless steel (316).

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Main Technical Parameters

| Trimmed Width (mm) |

3200 |

3600 |

3800 |

| Width of Jet (mm) |

3350 |

3800 |

4050 |

| Work Speed (m/min) |

200-300 |

200-300 |

200-300 |

| Diameter of holy roll (mm) |

220 |

| Cloth Paste Way |

Square taper pipe into the slurry,cloth pulp by the organic glass holey plate |

| Outline size (m) |

2.6*4.4*1.6 |

2.6*4.4*1.6 |

2.6*5*1.6 |

| Arrangement |

Left or right hand machine

|

Paper Making Machine Parts Paper Machine Air Cushion Headbox for Paper Pulp Industry Picture

Related Products

Dewatering Element

Forming Board Papermaking

Hydrofoils

Vacuum Box Papermaking

Bi-Vacuum Box/ Duo-Vac Box/Tri-Vac Boxes

Uhle Box/Bugley Box/Blow Box/Felt Suction Box

Top Wire Formers

Open Type HeadBox

Air Cushion HeadBox

Cylinder Former

Vat Cylinder Mould

Vat former

Shower Pipe Papermaking

Dryer Fabric Cleaner Papermaking

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!