Wheat Rice Straw Wood Bamboo Pulp Paper Mill Equipment High Speed Crescent Toilet Tissue Paper Making Production Machine

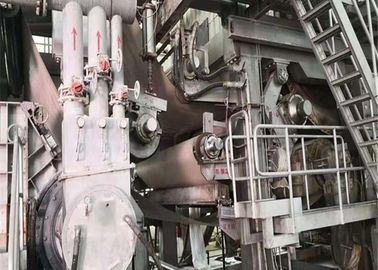

CRESCENT TISSUE PAPER MACHINE

This production line is mainly consisted of paper pulping system and Jumbo tissue roll making machine.

1.The pulping system is a process in which raw materials, such as waste books, paper, edge bleaching straw pulp board, bleaching wood pulp board, etc., are processed into fibrous water suspension which meets the requirements of paper making, and then sent to the paper machine by the flow system to meet the requirements of users.

2.Paper machine is to meet the paper making requirements of the pulp water suspension by the filter dehydration forming, mechanical extrusion dehydration and drying process then making into paper. The use of raw materials are: waste paper, old newspaper and white waste paper edges and so on. It can produce toilet paper, facial tissue paper, napkin paper, drawing paper and so on. The machine with reliable quality, stable performance, easy operation, energy saving and environmental protection, paper making machine is the ideal product in machinery field.

Specification

| Technical Parameters |

|

1.Main Product:

|

Toilet paper, napkin paper and drawing and so on |

|

2. Gsm:

|

15~30g/ |

|

3.Equipment form

|

Crescent |

|

4,Capacity:

|

20-22T/24h |

|

5.Raw paper width:

|

2850-2950mm |

|

6.Design speed:

|

450m/min |

|

7.Transmission speed:

|

300-400m/min |

|

8.Dynamic balancing speed:

|

600m/min |

|

9.Roller balance:

|

G2.5 class |

|

10.Dryer balance:

|

C4 class |

|

11.Winding paper roll:

|

C1.6 class |

|

12.Transmission mode:

|

Ac motor frequency control of motor speed digital distribution transmission |

|

13.Arrangement mode:

|

Right or left arrangement(selected by the user) |

|

14.Gauge:

|

3900mm |

| 15.Large equipment 1 |

Dryer cylinder:Ø3000mm×1 set |

Company Profile

We have passed CE, SGS, ISO quality system certification and all manufacture processes are conducted by the standard strictly.

Our company undertakes design, manufacturing, supply, erection and commissioning of paper machines & new pulp mill and modernization of existing pulp mill and paper machines on a turnkey basic. We also have innovative research team,always follow the

advanced technology of Finland,Denmark and Italy,Gemany;

Skilled and careful installation team.

Trade market:

Our machines sell good in more than 30 countries,such as Nigeria, Egypt,

Uzibekistan,Pakistan,America,Uganda,Turkey,Brazil,Fiji,Paraguay,Ethiopia,etc. High quality and perfect service have reserved customer's praise and more orders. We have established good relationship with many foreign countries because of our good quality and perfect service.

Buying Guide

In order to recommend the proper paper machine and make detailed technical proposal asap, please inform us the following technical parameters:

(1) what kind of paper do you want to produce?

(2) what kind of raw material you will use?

(3) how many tons do you want to produce per day (24hours)?

(4) what is the output paper width of jumbo roll?

(5) What is the output paper weight (grammage)?

Huatao Machinery can provide the whole paper mill service and solution.

Huatao has its own technological research department and keeps a closed technical cooperation relationship with the relative China pulp and paper research institute or university. What is more, Huatao positively organizes and attends technical communication activities within the industry and then effectively communicates with experts and enterprises equipped with themost advanced technology in the world.

Generally, Huatao R&D consists of five sections, including layout, pulping, paper-making, finishing line and electrical automation. Furthermore, each section will be getting more mature through the most current advanced technology.

Initially, the layout section includes some parts of environmental protection, construction, water supply, drainage and so on. And also, it mainly focuses on the most reasonable layout improvement for the pulp and paper mill, which will guarantee the newfactory with respect to staff security, environmental protection, logistics transportation, construction form and in turn reduce fixed investment and save operating cost as well.

Secondly, the pulping section concentrates more on research and development of new technology and equipment regarding fiber production improvement, recycling fiber utilizability, reducing pure water cost and so forth. Today, our researched pulping line has reached the advanced level and is very popular in the marketplace.

Thirdly, in terms of the paper-making section, relative technologies involving approach former, dehydration, drying, sizing and so forth will be researched continuously. Based on the traditional paper-making technology, we have already researched and developed a series of new paper machine. Especially, we are reaching the most advanced level for tissue machinery in the world.

In addition, as for finishing line section, our splitting rewinder is closed to the most advanced level in the world. Besides, different kinds of technologies will be continuously improved by us and our partner together in paper deep processing.

Finally, our electrical automation team is very young. However, based on the good quality of pulping and paper-making, the different levels of automatic control will become true as a customer real situation.

In a word, it is Huatao R&D that provides the best solution with customers.

When it comes to pulp and paper-making, as long as you are interested in Huatao, we definitely spare no effort to offer the optimal solution, from a spare part to the whole factory construction.

Our Services

1. Reasonable suggestions for selection of equipment.

2. Provide detailed description and assembly drawing , to make you more aware of the device's ability to work.

3. Engineers on-site equipment installation and commissioning.

4. Train and teach your worker to operate the paper machine,

5. Professional technical guidance and technical support during your production, make sure the device's work properly and production.

6. Equipment modification and updating.

7. We will testing installation machine in the factory workshop , to ensure safety and quality.

8. Supply Carbonless paper and Paper coating chemicals ,formulation ,technology and other suggestion to customers.

9. After-sales service for one year: equipment maintenance guidance.

10. Provide Turnkey projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!