Replacement 0.12mm Fine Mesh Urethane Screens for coal washing plant

HUATAO 0.12mm Fine Mesh Polyurethane Screens are engineered for coal washing plants, delivering precise particle separation and extended service life. Designed as direct replacements for TH48-30 screens, these high-frequency urethane screens combine wear-resistant materials with a lightweight, easy-to-install design. Ideal for harsh coal slurry environments, they reduce downtime and maintenance costs while ensuring optimal dewatering and classification efficiency. Durable construction withstands abrasion and corrosion, outperforming standard screens by 40-60% in lifespan. Upgrade to HUATAO for seamless compatibility, enhanced productivity, and cost-effective coal processing solutions.

Key Features: 0.12mm precision, compatible, abrasion-proof PU, extended durability, reduced downtime.

Aperture Size: 0.045mm (325 Mesh) ~8.0mm

Size: Regular as 1040*700mm, other size can be OEM

Open Area :35% - 40%

Replacement: TH48-30-Style Poly Urethane Screens

Application: Coal Washing Plant, Quartz Sand, Silica, Glass Raw Material

HUATAO guarantees rapid customization and delivery within 10-15 working days. Our screen mesh undergoes rigorous ISO-certified quality testing to ensure consistency and durability, backed by 24/7 technical support.

1) Product Description of Replacement 0.12mm Fine Mesh Urethane Screens for coal washing plant

The 0.075mm aperature High-Efficiency Polyurethane Urethane Screens working 6-12 months are designed to withstand the rigorous demands of mining operations. Made from high-quality polyurethane, these screens offer exceptional durability and wear resistance. They are ideal for separating and sizing minerals, aggregates, and other materials in mining and quarry applications.

2) Specification of Replacement 0.12mm Fine Mesh Urethane Screens for coal washing plant

| Specification |

Value |

| Material |

Polyurethane |

| Aperature Size |

0.045-8.0mm |

| Dimension Size |

1040*700mm as regular or OEM |

| Color |

Red or Orange |

| Durability |

High Wear-Resistant |

| Application |

Mining & Quarry |

| Wear Resistance |

3-8 times longer life span |

3) HUATAO focus to supply the Replacement 0.12mm Fine Mesh Urethane Screens for coal washing plant

As a leading manufacturer of mining screens, HUATAO offers the Durable Polyurethane Screen Mesh with a commitment to quality, reliability, and customer satisfaction. Our screens are designed for maximum efficiency and longevity, ensuring cost-effective solutions for your mining operations. With fast delivery and exceptional service, HUATAO is your trusted partner in mining equipment.

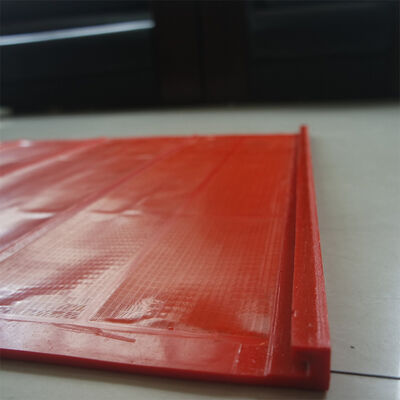

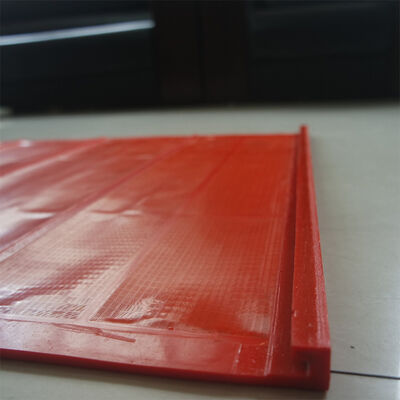

4) Images of Polyurethane Screen panel include:

A close-up of the Polyurethane screen panel hooks showing :

A photo of the Polyurethane screen panel in use in a slica Sand application.

5) Factory Production Processing of Poly Urethane Screen panels

The manufacturing of Replacement 0.12mm Fine Mesh Urethane Screens for coal washing plant involves advanced techniques to ensure precision, durability, and optimal performance. Below is a detailed overview of the production workflow:

1. Material Preparation:

High-grade polyurethane raw materials, including pre-polymers and curing agents, are meticulously selected based on abrasion resistance and

elasticity requirements. Additives such as UV stabilizers and anti-aging agents are blended to enhance longevity in harsh environments.

2. Mold Design & Fabrication:

Precision CNC-machined molds are crafted from stainless steel or aluminum, incorporating the exact aperture geometry (e.g., 0.045mm

wedge-shaped slots). Mold surfaces are polished to a mirror finish to ensure smooth demolding and dimensional accuracy.

3. Casting & Curing:

The liquid polyurethane mixture is vacuum-degassed to eliminate air bubbles.

It is then poured into preheated molds and subjected to controlled-temperature curing (80–120°C) in hydraulic presses. This step ensures

uniform density and structural integrity.

Post-curing thermal treatment further enhances tensile strength and chemical resistance.

4. Demolding & Trimming:

Cured screens are carefully demolded, and excess flash is removed using laser trimming or precision cutting tools. Edge sealing is applied to

prevent delamination during high-frequency vibrations.

5. Quality Control:

Aperture Verification: Laser scanners measure aperture sizes (e.g., 0.045mm ±0.005mm) and open area ratios (35%–40%).

Durability Testing: Simulated high-frequency vibration cycles (up to 3,600 RPM) assess fatigue resistance.

Material Certification: Shore hardness (85–95A), tear strength, and chemical compatibility are validated per ISO 9001 standards.

6. Surface Treatment (Optional):

Anti-static coatings or custom-colored finishes are applied for specific industrial requirements, such as explosive environments or visual

inspection needs.

7. Packaging & Logistics:

Screens are packed in moisture-proof, shock-absorbent materials and labeled for traceability. Custom sizes and OEM branding are

accommodated seamlessly.

HUATAO Hot-Selling Polyurethane Product List as below:

| Urethane Screen |

Tufflex Screen |

| Polyurethane Dewatering Screen Mesh |

WS 85 Modular Screen |

| Polyurethane Screen Panels |

Rotex Replacement Screens |

| Rubber Screen Panel |

Vibrating Screen Mesh |

| Self cleaning Wire Mesh |

Shale Shaker Screen |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!