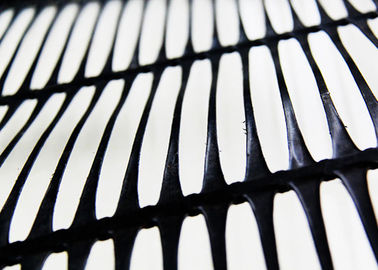

HDPE Uniaxial Geogrid Reinforcing Fabric UV Resistance With Chemical Stability

HDPE Geogeird Description

One-way stretch plastic geogrid pull body is a kind of polymer as the main raw material, adding some UV protection, anti-aging aids, through a one-way stretch so that the original distribution chain-shaped molecules scattered linear re-alignment high-strength geotextile material states. Much better than the traditional or existing reinforced materials, civil engineering is ideal reinforcement reinforcement reinforcement synthetic material.

HDPE Geogrid Specification

1. Strength: 30KN/M - 300KN/M

2. Width: 1m to 3m

3. Length: As request

4. Loading: 20ft container, 40ft high container

HDPE Geogrid Features

1. one-way high tensile strength, good creep resistance, chemical stability;

2. friction coefficient and gravel.

HDPE Geogrid Applications

Uniaxial geogrid with high strength, widely used in dam, tunnel, port, roads, railways, construction and other fields.

1. mainly used for retaining walls, abutments, steep slope engineering;

2. retaining walls and abutments belonging to the force structure, bear all the external loads: active earth pressure, the upper part of the structure of dynamic load, temperature, stress, long-term reinforcement material is under greater tension, and dynamic load under repeated action, the molecular structure of the material fatigue, which occurs attenuation performance, accelerated aging grid. To avoid structural reinforcement material due to creep deformation and greater, it should choose a high density polyethylene (HDPE) as raw materials unigeogrid.

Uniaxial Geogrid Specification

| Properties |

Test Method |

Unit |

PP 60 |

PP 80 |

PP 110 |

PP 150 |

PP 260 |

PP 300 |

| •Tensile Strength |

ASTM D 6637 |

≥kN/m |

60 |

80 |

110 |

150 |

260 |

300 |

| •Strength at 2% Elongation |

ASTM D 6637 |

≥kN/m |

17 |

26 |

32 |

45 |

97 |

105 |

| •Strength at 5% Elongation |

ASTM D 6637 |

≥kN/m |

35 |

48 |

64 |

90 |

185 |

195 |

| •Elongation Ratio |

ASTM D 6637 |

≤ % |

10 |

10 |

10 |

10 |

10 |

10 |

| Dimensions |

| •Roll Width |

- |

M |

100 |

100 |

50 |

50 |

50 |

50 |

| •Roll Length |

- |

M |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!